In the meticulous world of environmental health and safety, one misstep with expired chemicals can cascade into a crisis. It can impact not just regulatory compliance but the very well-being of your workforce.

You know the drill. The incessant tracking of chemical inventories, the nerve-racking audits, and the constant vigilance against the ticking time bomb of chemical expiration dates. It’s a high-stakes game where the cost of error is not just financial but can compromise safety and reputation.

This is where the power of chemical inventory software becomes not just a convenience but a necessity. It’s designed to relieve you from the relentless pressure of monitoring and managing chemical assets by transforming a labyrinth of data into clear, actionable insights. Read on to learn why overlooking this vital aspect can be perilous and how embracing it can be transformative for your business.

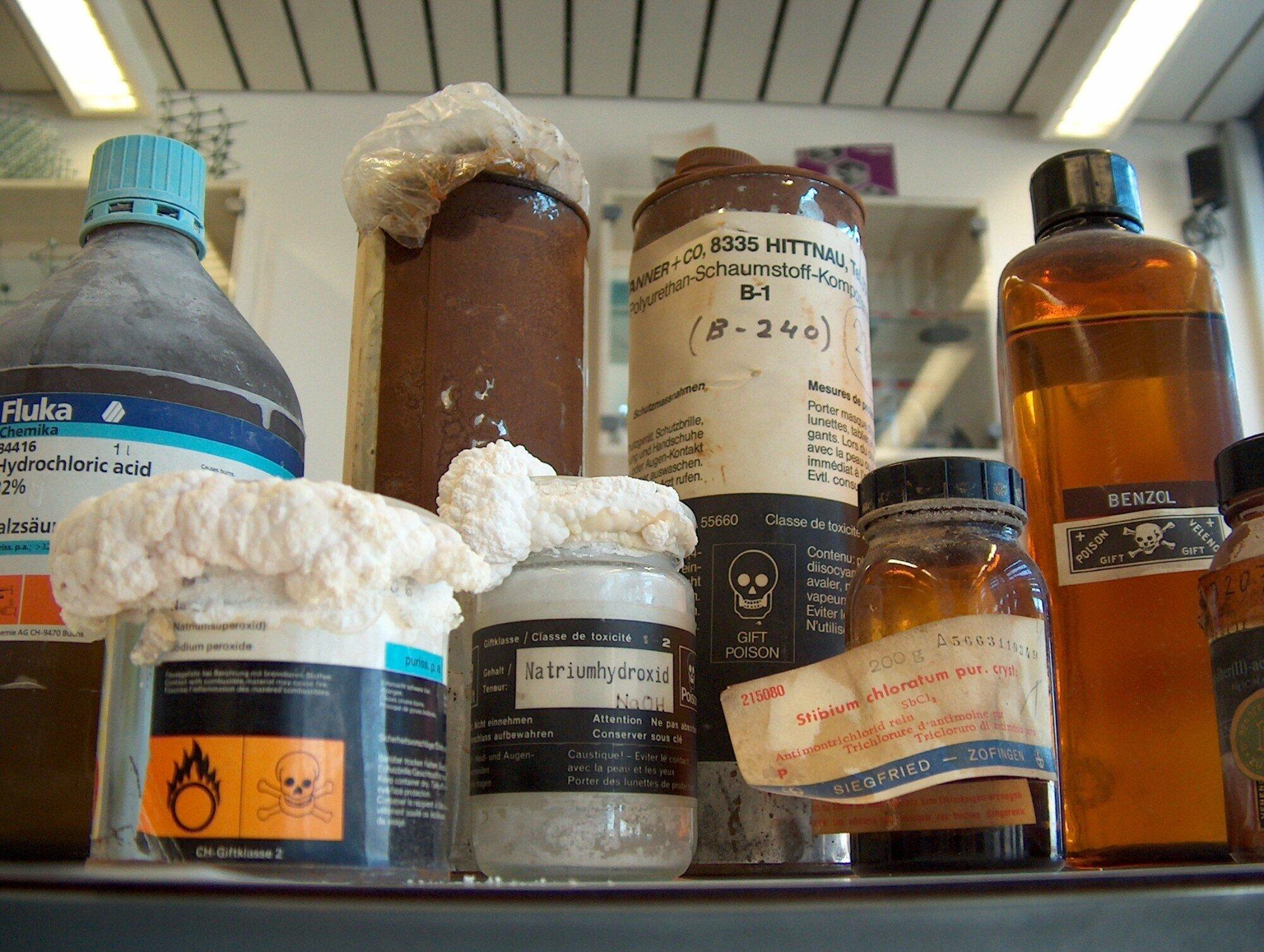

The Risks of Expired Chemicals

The hazards associated with expired chemicals in the workplace are substantial and multifaceted. One of the primary risks is the potential for these chemicals to become unstable and reactive over time. It can lead to fires, explosions, or the release of toxic fumes.

These incidents not only endanger the health and safety of workers but also pose significant environmental risks.

Moreover, the use of expired chemicals can result in ineffective processes or products. This can lead to financial losses and damage to the company’s reputation. In certain industries, like pharmaceuticals and food manufacturing, using expired ingredients can have serious health implications for consumers.

Another risk involves regulatory compliance. Many industries are governed by strict regulations regarding the handling and disposal of chemicals. Using or storing expired chemicals can lead to fines and legal action, as well as increased scrutiny from regulatory bodies.

Key Features of Effective Chemical Inventory Software

Effective chemical inventory software is essential for maintaining a safe and efficient workplace. Especially when dealing with hazardous materials. Here are some of the key features that make such software indispensable.

Real-Time Inventory Tracking

One of the most critical features of chemical inventory software is the ability to track inventory in real-time. This means that at any given moment, you can have a complete and updated picture of the chemicals you have on hand.

This feature is crucial for maintaining chemical safety as it helps in quickly identifying any expired chemicals and ensuring they are properly disposed of. Real-time tracking also aids in avoiding stock shortages or overstocking. This can be both costly and hazardous.

Regulatory Compliance and Data Updates

Navigating the complex world of regulatory compliance can be daunting. Effective chemical inventory software simplifies this process by keeping up with the latest regulations and ensuring your practices comply.

For instance, it can automatically update safety data sheets (SDSs) and track regulatory changes that affect how chemicals should be stored and handled. This not only helps in avoiding legal pitfalls but also ensures a safe working environment.

Multi-Site Management

For businesses operating across multiple locations, managing chemical inventories can be challenging. Advanced chemical inventory software allows for seamless multi-site management.

This means you can oversee chemical storage and usage across all your locations from a single platform. It ensures consistency in safety practices and inventory management, regardless of the geographical location of your sites.

User-Friendly Interface and Reporting

A user-friendly interface is vital to ensure that all staff members can effectively use the software. Clear, intuitive controls and easy navigation make it simpler for employees to track and manage chemical inventories.

Additionally, the ability to generate detailed reports is invaluable. These reports can provide insights into:

- Usage patterns

- Potential risks

- Areas for improvement

Integration with Other Systems

Integration with other systems, such as ERP or supply chain management software, enhances the functionality of chemical inventory software. This integration allows for smoother operations. Information flows seamlessly between different systems which reduces manual data entry and the potential for errors.

Cost-Effective Solutions

Finally, cost is always a consideration. Many effective chemical inventory software solutions offer flexible pricing models, including no upfront costs which makes them accessible for businesses of all sizes.

This approach allows companies to implement state-of-the-art chemical management systems without a significant initial investment. It ensures safety and compliance are not compromised due to budget constraints.

Implementing Chemical Inventory Software in Your Workplace

Implementing chemical inventory software in your workplace involves several crucial steps to ensure safety, compliance, and efficiency. Here’s a guide to help you integrate this essential tool into your existing safety protocols:

Conduct Chemical Inventory Assessments

Begin by thoroughly assessing your current chemical inventory. This includes identifying all chemicals present, whether in storage, active use, or awaiting disposal.

Categorize and Label Chemicals

Next, categorize chemicals based on hazard classification, compatibility, and storage requirements. Implement a labeling system that clearly indicates each chemical’s identity, associated hazards, and any special handling instructions. Ensure all container labels are visible, legible, and comply with regulations like GHS labeling requirements.

Safe Storage Practices

Store chemicals in designated areas suitable for their specific properties and hazards. Segregate incompatible materials and clearly label storage areas.

Use appropriate storage containers, such as chemical cabinets, to minimize the risk of spills, leaks, or contamination. Regular cleaning and proper ventilation of storage areas are also crucial.

Implement a Tracking System

Keep a detailed log of all chemicals on-site, including chemical purchase dates, daily or weekly usage, and quantities. Regularly reconcile inventory records with physical counts to ensure accuracy.

Track Expiration Dates and Dispose of Waste Safely

Establish a system to monitor chemical expiration dates and dispose of them before they become hazardous. Use a first-in, first-out (FIFO) approach to minimize the risk of using expired chemicals. Have clear procedures for safe disposal of chemicals, following local, state, and federal regulations.

Safeguard Your Workspace with Advanced Technology

In the world of chemical safety, vigilance is key. Online-SDS epitomizes this vigilance through our state-of-the-art chemical inventory software. Our solutions are crafted to ensure that managing your chemical assets and mitigating risks associated with expired chemicals becomes seamless and efficient.

With Online-SDS, you gain not just a tool but a partner in upholding the highest standards of chemical storage and safety. Ready to revolutionize your approach to chemical inventory management? Book a demo and witness firsthand how we can transform your chemical safety protocols.